- Av. de Sentmenat, 159 - 08213 Polinyà (Barcelona)

- 93 747 08 02

- info@cgm-sl.com

Industrial Maintenance

Actions preventive and predictive in industrial machines

Gas installations

- Repair: industrial burners and boilers.

- Preventive / predictive maintenance: Generation of all the necessary documentation for audits.

Cooler equipment

- Repair: industrial cooler equipment.

- Preventive / predictive maintenance: Generation of all the necessary documentation for audits.

Air compressors

- Repair: industrial air compressor equipment.

- Preventive / predictive maintenance: Generation of all the necessary documentation for audits.

Peripherals

- Repair: Industrial compressors.

- Preventive / predictive maintenance: With the completion of maintenance, all the necessary documentation for audits is generated.

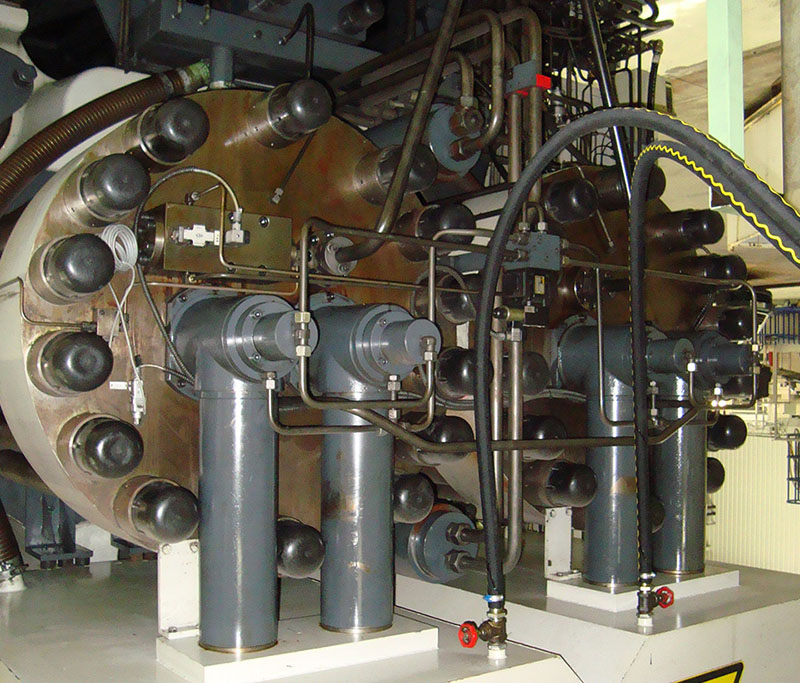

Injection molding machines, extruders and presses

- Electrical repair: Wide range of presses, extruders and injectors (ENGEL, DEMAG, BMB, FERROMATIC, etc.).

- Mechanical repair: repair of closures by pad, change of columns, repair of plastic groups, change of lubrication system, etc.

- Hydraulic repair: change of pumps, motors, valves, regulators, groups, proportional flow and pressure, change of cylinder linings, etc.

- Repair of accumulators: Condition control, pressure control, nitrogen filling, repair, etc.

- Preventive / predictive maintenance: With the completion of maintenance, all the necessary documentation for audits is generated.

Lines of material feeding and cooler

- Installation: Assembly and modification of lines for material supply and cooling of the injectors and extruders.

- Control panels: Construction of specific control panels for these installations.

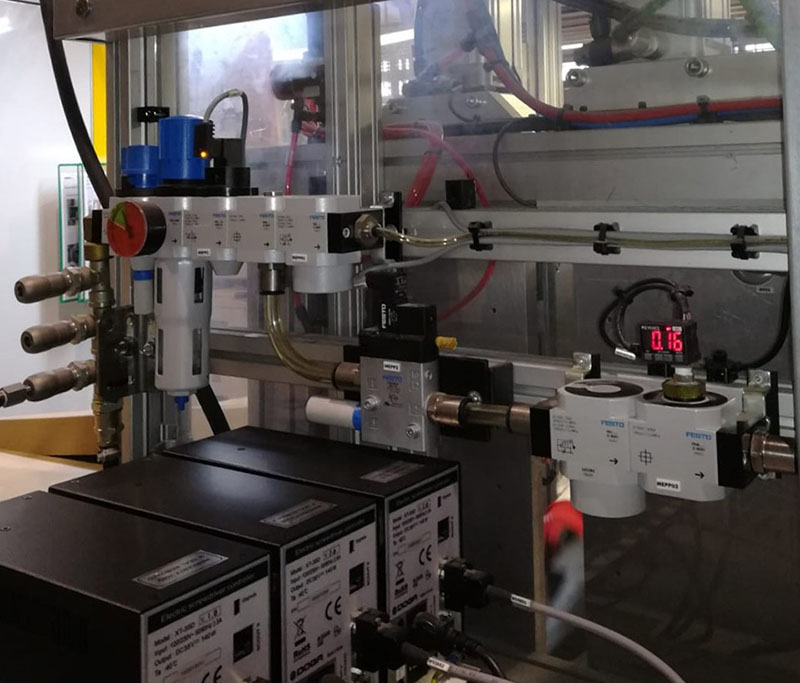

Pneumatic installations

- Repair: Repair of any type of pneumatic installation.

- Preventive / predictive maintenance: With the completion of maintenance, all the necessary documentation for audits is generated.

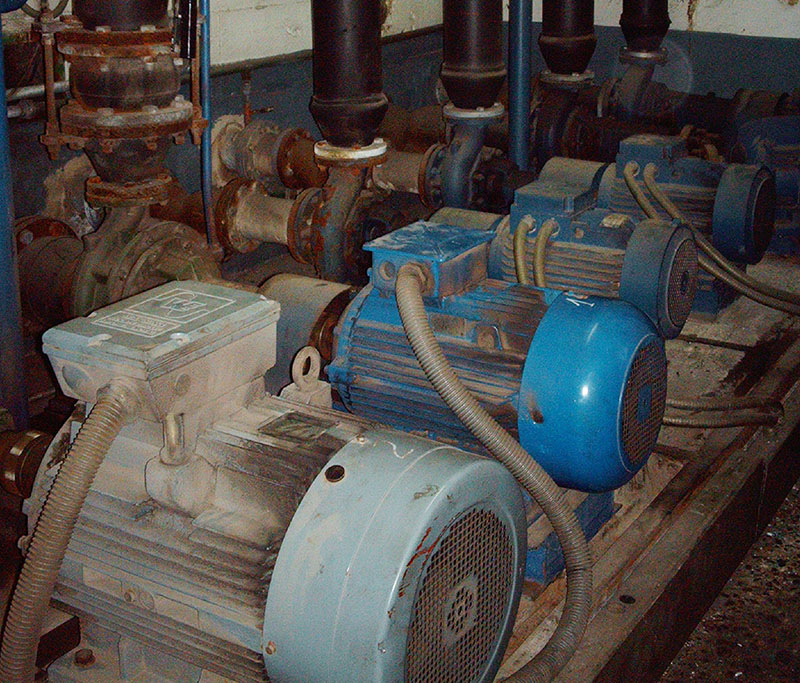

Hydraulic installations

- Repair: Repair of any type of hydraulic installation.

- Preventive / predictive maintenance: With the maintenance, all the documentation necessary for the audits is generated.

- Detection of faults in proportional cards in control valves and proportional valves.

- Review and check of variable flow pumps: check of pump flow rates and control electronics.

- Review and check of pump motors: electrical and mechanical parts and couplings.

- Upgrading of proportional and pump control cards (discontinued or obsolete) by universal Rexroth cards (VT cards).

- Proportional valve revision and repair.

- Review and repair of hydraulic breakdowns in machines, injectors, presses, concrete pumping groups and drilling machines.

- Upgrade from S5 to S7 in machine controls and change of control in presses.

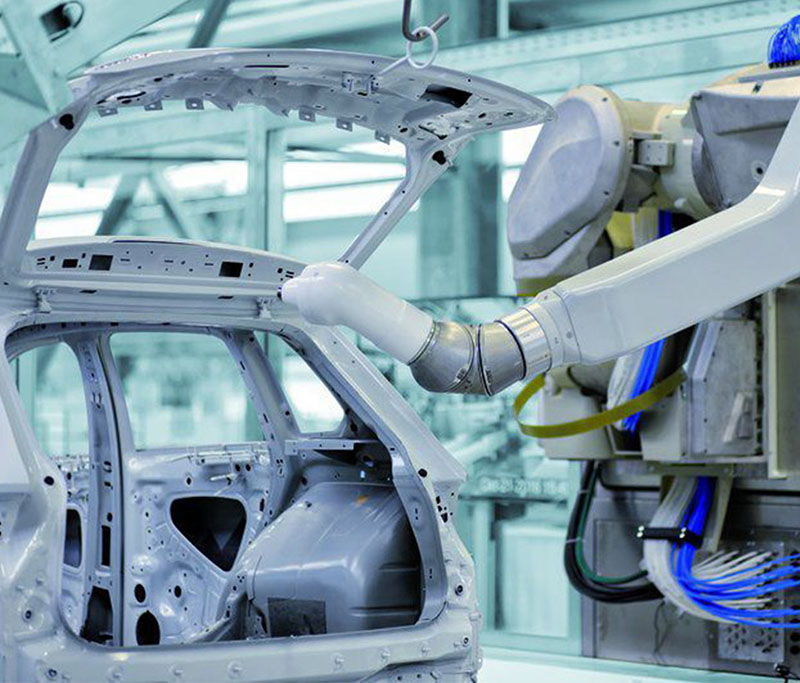

Paint lines

- Preventive / predictive maintenance of all the components of the line (flaming equipment, motors, turbines, ionizing equipment, water pumps, etc.): With the completion of maintenance, all the necessary documentation for the audits is generated.

- Modification of the line: Mechanical modification, incorporation of new cabins to it, etc.

- Technical cleaning: Cleaning of the most sensitive components of the line (turbines, ionization bars, filter change, etc.)

- Electric rehabilitation: Modification and updating of control panels.

- Reduction of costs and control of currents: Reduction of the energy consumption as well as total control of the supply and extraction streams of the cabins.

- Automation of the cabins: Incorporation of paint robots, for flaming booths, primer, color and varnish.

- Security and pressurization: Installation of security systems and insulation for the cabins (double locking system, limit switches, etc.)

- Preventive / predictive maintenance: With the completion of maintenance all the necessary documentation for audits is generated.

Human Resources

Technical workers available to cover work casualties or vacancies in the maintenance department: We have the profile of the personnel suitable to your needs (highly qualified technicians, first and second officers, electro-mechanical and hydraulic) to cover eventual casualties or vacancies in the department of maintenance.