- Av. de Sentmenat, 159 - 08213 Polinyà (Barcelona)

- 93 747 08 02

- info@cgm-sl.com

Industrial engineering

Development of projects, modifications and programming

Energy efficiency

Improvements in consumption, cycle times, life hours. Study of points of improvement and optimization.

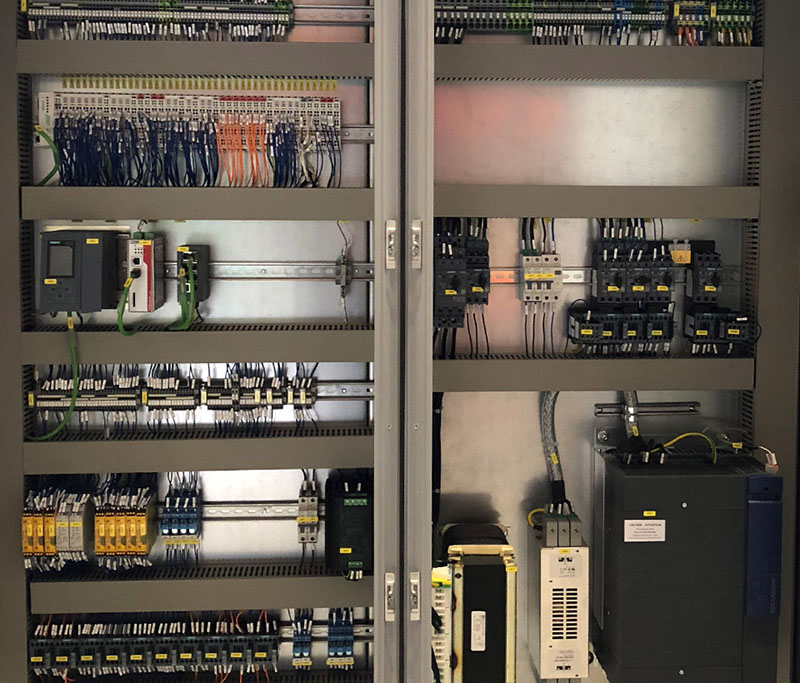

Electrical enclosures

Design and assembly of control panels: For all types of electrical installations. Wiring of electrical enclosures: Both control and power. Technical Office: Creation and generation of all the necessary documentation for the projects (plans of the tables, electrical diagrams, etc.)

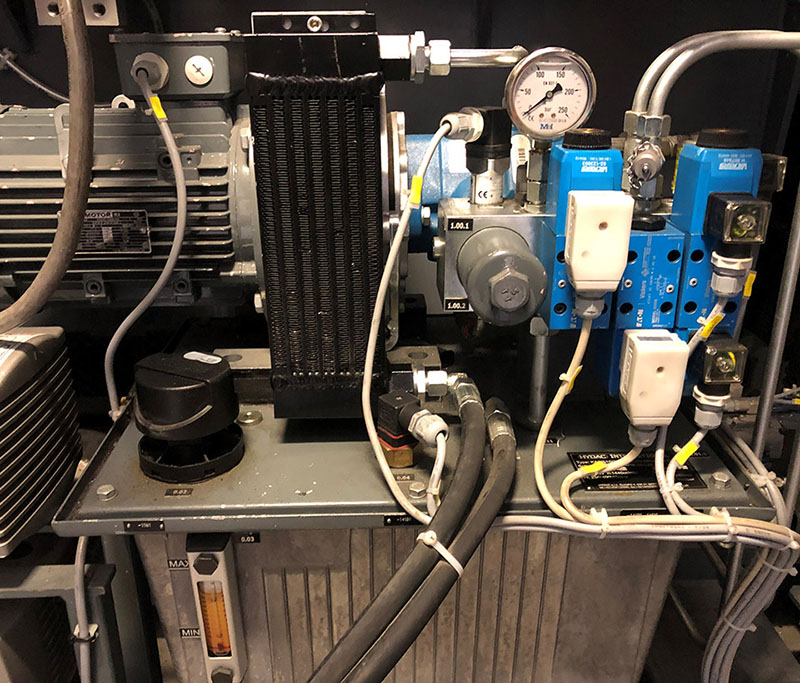

Hydraulic systems

- Hydraulic control units: Design and construction of autonomous control units or integrated in the machines, with independent control panel (for the maintenance workshop) or associated with the machine. For control of nodes, etc.

- Sequential control units: Design and construction of autonomous sequential control units or integrated in the machines, with independent control panel (for the maintenance workshop) or associated with the machine. For the control of the valves of the nozzles of the molds.

- Design and assembly of control panels for hydraulic power stations: For all types of electrical installations.

- Wiring of electrical panels: For the control of hydraulic systems.

- Rehabilitation of equipment: Update of control panels and components.

- Security: Assembly of security systems for the equipment (establishment of safe areas by barriers, foot barriers, etc.)

- Technical Office: Creation and generation of all the necessary documentation for the projects (plan drawings, hydraulic, electrical diagrams, etc.)

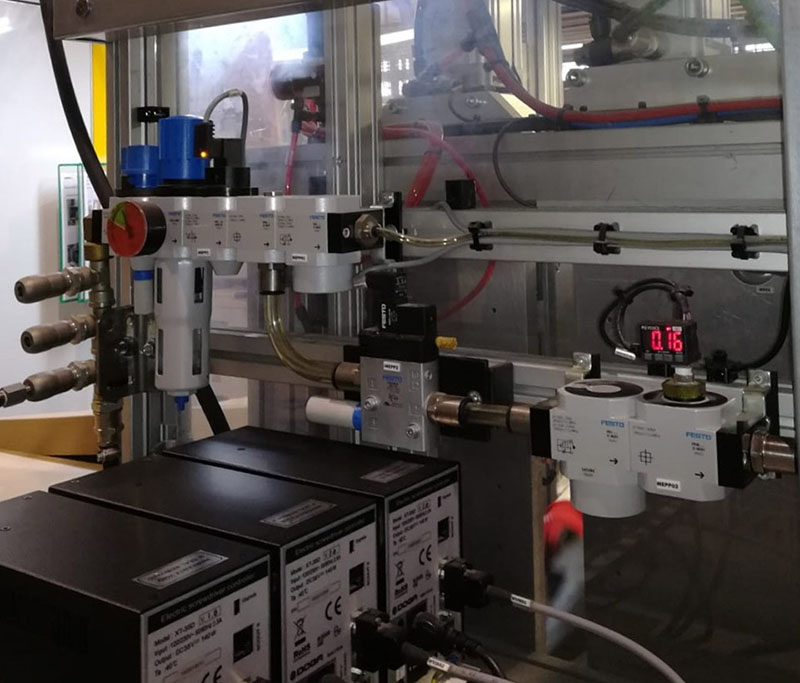

Pneumatics

- Design and assembly of pneumatic panels: For all types of installations, machines and tools.

- Wiring of electrical panels: For the control of pneumatic panels.

- Rehabilitation of equipment: Update of control panels and components.

- Security: Assembly of security systems for equipment (establishment of safe areas by barriers, etc.)

- Technical office: Creation and generation of all the necessary documentation for the projects (plan of the tables, pneumatic, electrical diagrams, etc.)

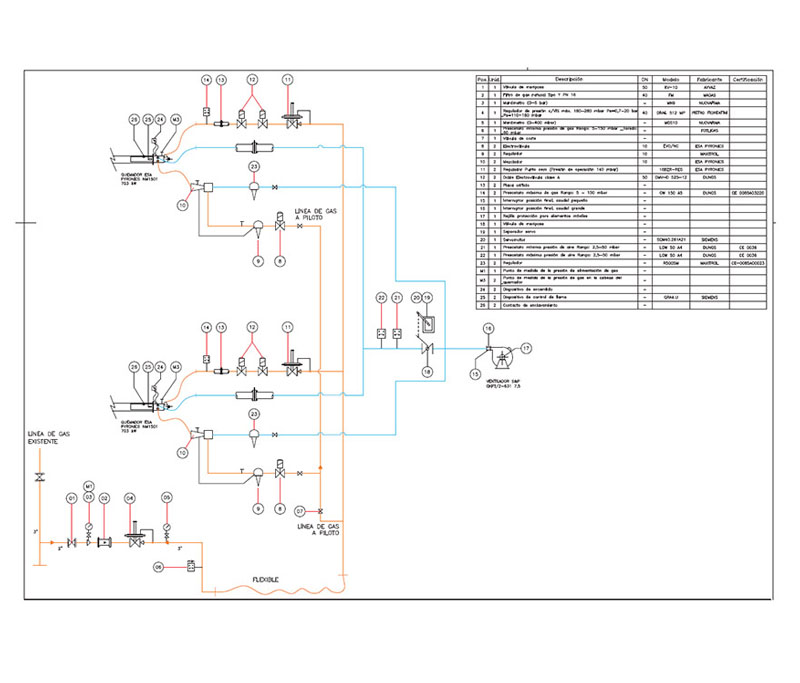

Gas

- Construction and assembly of special equipment for surface treatment with flame: Suitable for removing small burrs in plastic parts, improving adhesion for sticking labels, etc.

- Construction and assembly of equipment for the generation of plasma: Improvement of the adhesion for the painting of pieces (both water-based and solvent-based).

- Construction and assembly of electrical control panels for boilers and burners: Adaptation of the safety regulations to new regulations, updating of electrical panels, construction of new tables, etc.

- Rehabilitation of equipment: Update of control panels and components.

- Legalization of facilities and equipment: Review and generation of the necessary documentation for its legalization.

- Security: Assembly of security systems for the equipment (detection of gases, flame, temperature, etc.)

- Technical Office: Creation and generation of all the necessary documentation for the projects (plans of the tables, electrical diagrams, etc.)

Robot programming

- Creation and modification of robots manipulator programs ABB, Fanuc, Sepro, etc.

- Creation and modification of painting programs.

Cell design

Communication between the robot and the machine. Assembly of security systems for work areas (protection bars, limit switches, push buttons, bimanual, barriers, etc).

Tool design

Claw construction and vacuum clamping systems or drives for various applications. Part rotators, fasteners, lifting platforms, etc.

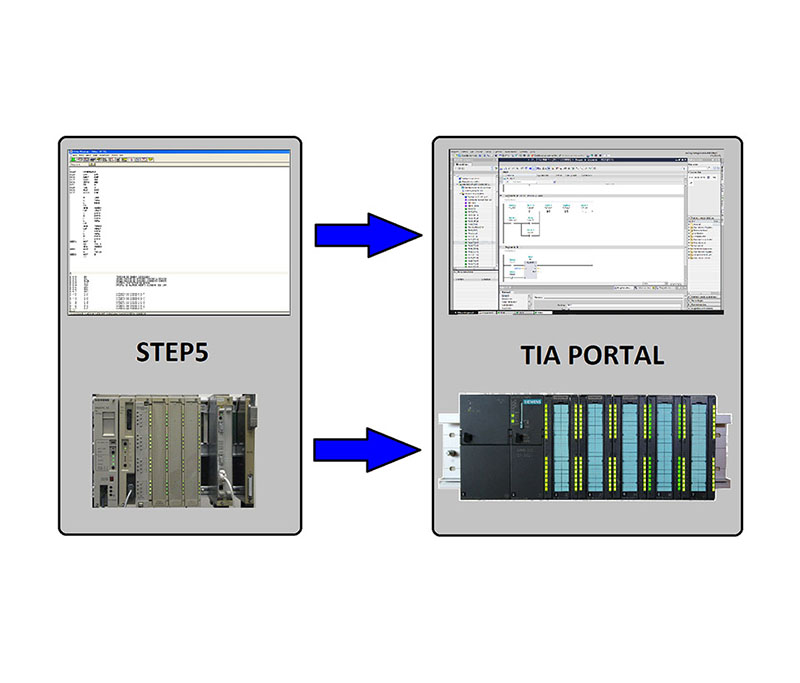

PLC Migrations

Migrations from obsolete PLC programs to current equipment as well as the migration and adaptation of programs between different PLC manufacturers.

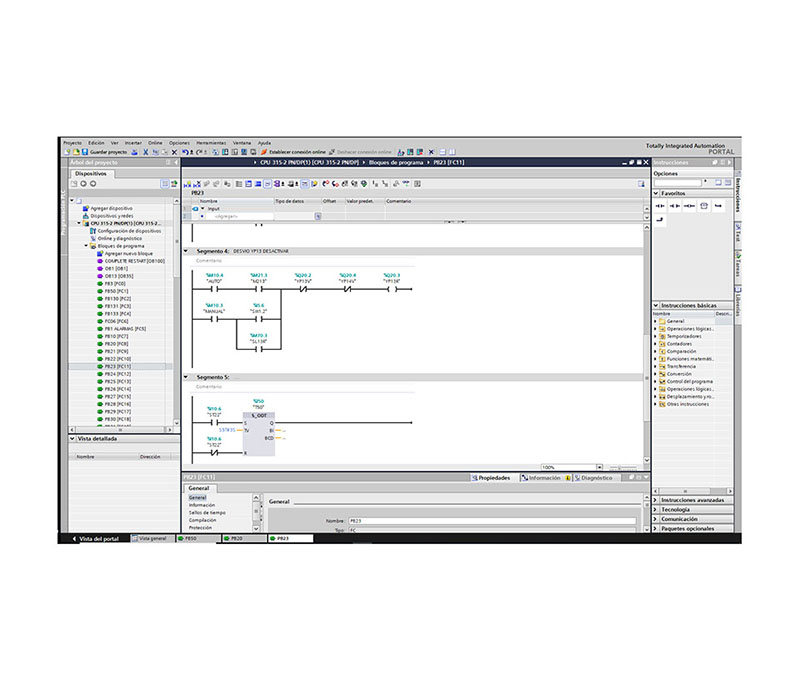

Programming

Creation and modification of existing PLC and SCADA programs through programming languages such as TIA PORTAL, DOPSOFT, ISPSOFT, OMRON, PROFACE, etc.